The surgeon can be studied from an ergonomic viewpoint already used with profit in industry, with the aim of designing tools to fit the human operator. In this paper, analysis of the grips of the hand is the basis for a new needlehoider design which makes suturing quicker and more accurate. It is related to the "internal precision grip" of the hand, commonly used for fine work, now added to the recognized power and precision grips. A tool handle can be designed to rotate within this grip, allowing the wrist to be kept steady during suturing.

In developing this design, the precision grips of the hand are observed in detail, and reference is made to other types of skilled manual activity. The measurement of forces exerted during suturing is illustrated.

Over the years, many types of surgical needleholder have been devised. The design presented on this occasion is one based on an ergonomic analysis of hand grip, an approach which is new but has fundamental applications to many types of hand tool.

THE GRIPS OF THE HAND

In 1956 Napier classified the grips of the hand into the precision grip and the power grip. The former is the one used in writing with a .pen, and the latter for gripping a hammer. He discussed gradations between these grips, and also listed the hook grip, analogous to that of apes in swinging from tree to tree. Other varieties of grip may be added, such as the "interdigital grip" used in holding a cigarette, and the "ulnar storage grip" for storing objects in the palm by the ring and little fingers while the remaining three digits carry out some other movement. (Patkin, 1965). Yet to be described is the "internal precision grip" used by watchmakers, eye surgeons, and diners wielding a knife and fork (see below).

The precision grip

The precision grip described by Napier merits further study, because it is sometimes confused with a simple pincer, comprising the tips of the thumb and index finger, whereas at least two more components must be considered.

The first of these is the use of the ulnar edge of the hand and the knuckles of the ring and little finger to steady the rest of the hand on the working surface. Where this is not possible, as in sign-writing, when the working surface might be smudged, the painter rests his hand on a "maul-stick" to minimize the effect of physiological tremor on his work. Sometimes no support is available, as in writing low down on a blackboard with the wrist fully extended, and the writing is laboured and untidy.

Analogous postures are seen sometimes during surgical operations, for example the use of an overlong needleholder while inserting fine skin sutures. For many delicate manoeuvres carried out at eye level, away from external support, the hands are steadied against one another, as in threading a needle, except when this is done by an inexperienced or kinetically naive person. Such manoeuvres can be taught deliberately.

,

The remaining component of the precision grip is the knowledgeable patch of skin near the apex of the cleft between thumb and index, over the second metacarpal bone or its adjoining phalanx. This area of skin helps to steady a pencil or fine tweezers. Its non-use gives a marked but seldom analysed disadvantage in working with a short stub of pencil or chalk.An occasional addition to the precision grip is a fulcrum for the tool to rest on, reducing the amplitude of movement and markedly reducing physiological tremor. This is seen in sharpening a chisel on a rotary grinder, in resting a cutter on the tee-piece of a watchmaker's lathe, or in steadying a needleholder against the index finger of the other hand.

There are at least two practical implications of the "pen" type of precision grip. One is that the handle of a precision tool must be long enough to bridge between the pincer grip and the thumb cleft (usually S or 9 cm). The other is that in this style of working the tool cannot be held horizontally near the working surface, as in the usual posture for suturing.

The internal precision grip of the hand

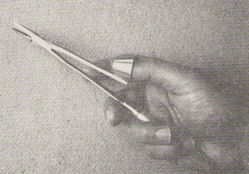

For tools held horizontally while precise work is carried out, another type of grip is used. It is seen in the use of fine ophthalmic needleholders, and is similar to the grip of an adult holding a dinner-fork, except that in this case the wrist or knuckles are supported. Because the handle is placed inside rather than outside the palm, it may be termed the "internal precision grip".

The internal precision grip has two main components. One is a pincer by the tips of the thumb, index, and perhaps middle finger. The other is where the ring and little fingers hold the butt of the handle next to or on to the hypothenar eminence. The latter component is in fact the "ulnar storage grip", and its part in increasing dexterity of movement will become apparent.

Analysis of the internal precision grip has important implications for instrument design. First, the length of the handle must be equal at least to the distance from the tip of the curved index to the hypothenar eminence, without being long enough to foul on the front of the wrist when the joint is flexed.

Next, the handle must be thick enough to indent the skin until it presses on firmer, deeper structures, allowing pressure to be exerted over a sufficient area to avoid producing grooves in the skin, which inhibit strength of grip (Patkin, unpublished material). It must not be so thick that less than halt of the handle circumference is gripped, when slipping could occur. In practical terms, the butt of the handle should be one or two centimetres in diameter, thinner when fragile material with little resistance is being worked on, and thicker when the hand must exert greater pressures.

Third, the diameter of the handle where it is gripped by the finger tips should be enough to almost separate the pulps of the finger tips when these are deformed and splayed by mild pressure. A distinctive feature of the "internal precision grip" is the amount of rotation that can be applied to a cylindrical handle by attempting to rub the thumb and index finger against one another.

The degree of rotation increases as the diameter of the handle shrinks to the point where it is too thin to have effective contact with the skin. If the handle is a flat one, like that on most scalpels or watchmaker's tweezers, no such rotation is possible. Where fine tweezers are used for a task such as handling microcircuit chips, the whole forearm must be moved to rotate the chip, and possibly the upper arm as well needs to be used. The addition of hemicylindrical lugs to the handles of watchmaker's forceps confers on this instrument the property of rotatability to a limited extent.

ROTATABILITY OF INSTRUMENTS

The factor of rotatability is a crucial one for fine work. Most suture needles are shaped in a halt-circle, and the act of stitching requires them to follow a circular track, in delicate tissue, to avoid tearing. In most general surgery this means that the forearm must be pronated through two right angles, for a forehand stitch. If the starting or finishing position is an awkward one, the result is ungainly shoulder shrugging or fumbling during the required manceuvre.

On the other hand, with a rotatable needleholder, pronation and supination are movements of the instrument being rolled between the thumb and index, and not of the forearm or shoulder. The forearm can be steadied against a convenient or preplanned support, or its own natural movement can be added to the range of rotation of the instrument which now becomes 360 degrees.

Rotatability is already a feature of some fine needleholders, such as the Pierse microsurgical needleholder made by Keeler. Salmon (1968) described a cylindrical needleholder handle whose jaws were operated from a remote control footpedal by hydraulic pressure, but which was to be held like a pen, rather than in the internal precision grip described.

CONTROL OF JAW MOVEMENT

Where a hand tool has moving parts such as jaws, blades, or a power switch, some form of trigger function of the hand is needed to operate it. A trigger function has been defined (P'atkin, 1967) as a hand function in which the tool is kept steady within the hand while digits move a part of it independently. This is seen with such examples as a gun trigger worked by the index, the end button of a hand brake worked by the thumb, a similarly placed power switch for electric drills designed by E. R. Tichauer, the ratchet of a Halsted needleholder released by the little finger, or the complex compression-torsion movement of releasing an artery forceps.

For fine suturing, it is best to have the rest of the hand unsteadied as little as possible by this trigger function, to minimize movement of a needle already placed in fragile tissue, apart from the question of economy of movement. Such tissue may tear with a pull of thirty or forty grams on the needle, while it takes 20 or 30 times as much force as this to apply or release the ratchet of a Castroviejo needleholder.

The thumb appears to be the digit best placed to move independently of the other digits, and simple measurements also confirm that it is the strongest. Trial and error as well as more formal analysis shows that a ring for the thumb is best placed in a plane at right angles to the conventional one of the blades or jaws of scissors or artery forceps.

This thumb ring allows control both of jaw movement and of instrument rotation. It has the disadvantage that the thumb can slip too deeply through the ring, so that some fumbling is necessary to regain a working posture of the hand. One solution was to have a simple platform for the thumb to press on, with a return spring.

However, the best design for the thumb handle appears to be a conoid, which the thumb can fit into with comfort, but not slip through. Compared with a ring, there is more surface area for the thumb pulp to contact, avoiding the denting effect which inhibits grip strength.

Jaw length can be shortened in a needleholder with a thumb handle of this type because of the wider range of opening movement made possible by the use of the tip of the thumb instead of its more proximal part. This in turn allows a greater leverage to be exerted on the needle for the same effort, and the needle is much less likely to slip or twist. The opposite effect of a poor mechanical advantage is seen with Gillies' needleholder, in which the jaws are separated from the hinge by scissor blades, and any tough tissue encountered by the needle point makes it twist within the jaws.

THE COMPLETED DESIGN

The final result, at this time, is a needleholder whose two handles are quite distinct (Figure 1). One is designed for the thumb, the other for a precise grip by the index and middle fingers, and for storage or rotation within the palm and the ring and little fingers.

The thumb handle has a hollowed conoid, large enough at its base to accommodate the pulp, and narrow enough at its end to stop the thumb slipping through or catching. It is set with its axis parallel to the handle in order to allow natural movement in the mid-range of thumb flexion-extension and abduction-adduction. With abduction of the thumb, the conoid rotates or "pronates" the needleholder within the internal precision grip of the hand, while the forearm can be kept immobile and steadied. Adduction and subsequent flexion of the thumb supinate the needleholder. Almost half a circle of rotation is available from these actions, enough for most suturing, and more than enough when combined with the freedom of a mobile forearm as well.

The palmar handle is cylindrical. It is proportioned to fit the ulnar storage grip near its butt, and the index and middle fingers where they help to form the pincer near its working end.

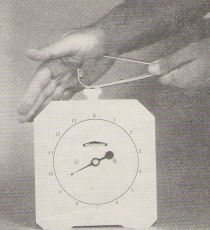

A ratchet was incorporated in one version of the needleholder, but this extra security of grip was found superfluous after some practice because of the comfort and strength provided by the basic design. Omission of the ratchet has simplified and quickened suturing and has avoided the rocking motion otherwise imparted to a needle on letting it go. Observations with kitchen scales showed that a force of between 2 and 4 lb is necessary to apply, let alone release, the ratchet of a Hegar needleholder of best quality, and a force of 9 lb weight is necessary to release the ratchet of a Matthews needleholder of good quality (Figure 2).

ADVANTAGES AND DISADVANTAGES

The main disadvantage of this type of needleholder is that a new set of movements must be learned by the operator, a situation comparable to that of buying a new type of motor-car or taking up a new sport. This is likely to deter surgeons well set in their ways and satisfied with the results of their present suturing technique.

For those with unusually small or large hands, a different size of thumb cone may be necessary. The palmar handle is more easily altered to individual preference, either by screwing in a new one, or by threading some rubber tubing over the handle.

For many operators who may take the trouble to master this instrument, the likely advantages are:

1. Security of a firmer hand grip, saving the need for a ratchet, and simplifying the elements of motion for each individual stich. The tremor on releasing the ratchet is eliminated, an important factor when dealing with more delicate tissues.

2. Rotatability of the instrument saves the need for much of the usual movement of the forearm, allowing increased steadiness. For heavier suturing, a full circle of 360 degrees of rotation is achievable by pronation and supination of the needleholder within the hand.

3. The instrument can be held in the "ulnar storage grip" of the hand, to save putting it down and picking it up again, saving many elements of motion in suturing.

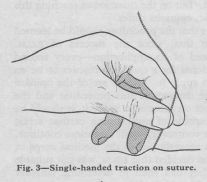

4. Another form of storage is possible, namely that of holding the instrument by the thumb and index finger, and allowing the middle, ring, and little fingers to grip a suture in the "suture storage grip". This frees the hand to help pull a suture snug in the tissue, and avoids the risk of unthreading a needle or straining the joint in the case of an atraumatic suture (Figure 3).

ACKNOWLEDGEMENTS

Messrs Ramsay Surgical of New South Wales provided at no charge a number of needleholders to form the starting point for the design shown. The conversion and additions were carried out from my rough models by Mr G. W. Olsen of Dungog. He contributed to the final design and completed the instruments with sufficient polish for routine surgical use. Many surgical friends have helped with their most useful comments and criticisms

ADDENDUM

Since this paper was submitted for publication, much use has been made of a smaller version of the ergonomic needleholder for fine skin suture, with particularly satisfactory results. This model is made from a pair of mosquito forceps with the jaws shortened and made smooth. A long version of the same type of instrument has been designed for deep cavity work, and a pleasing feature has been the slight hand-grip necessary to secure the needle, as a result of the longer handles and greater leverage (see Figure 4).

REFERENCES

Napier, J. R. (1956), "Prehensile Movements of the Human Hand", J. Bone Jt Surg., 38-B(4) : 902.

Patkin, M. (1965), "The Hand Has Two Grips: An Aspect of Surgical Dexterity", Lancet, 1: 1384.

Patkin, M. (1967), "Operative Surgery, the Human Hand, and Handle Design". Paper presented at the Fourth Annual Conference of the Ergonomics Society of Australia and New Zealand.

Salmon, P. A. (1968), "A New Technique of Microsuture for Blood-Vessel Anastomosts", Brit. J. Surg., 55: 58.

Wilson, Edward (1961), "The Time Factor in Surgery", Med. J. Aust., 2: 699.

Australasian Medical Publishing Company Limited 71-79 Arundel Street, Glebe, Sydney, N.S.W., .2037

-o0o-

Ergonomic Design of a Needleholder

Michael Patkin, M.B., B.S.(Melb.), F.R.C.S.(Eng.), F.R.C.S.(Edin.),

F. R. A. C. S.

Dungog, New South Wales

Address for reprints: Dr Michael Patkin, Cangon, Dungog, N.S.W., 2420.

_________________

This design for a surgical needleholder was awarded a Prince Philip Prize for Industrial Design in 1971

The adjudicator for the Industrial Design Council of Australia was the redoubtable Sir Edward ("Weary") Dunlop. Weary was the great Australian national hero who had performed heroics of surgery on the notorious Burma Railway where tens of thousands of Australian soldiers died of starvation, disease and brutality at the hands of their Japanese captors. He had displayed huge personal courage defying them as well, taking huge risks to himself to protect the prisoners as best he could.

In private life after the Second World War, like also heroic Sir Albert Coates, her returned as a surgeon to the Royal Melbourne Hospital, where he tackled the high risk high mortality problems of treating cancer of the oesophagus. Junior doctors, respecting this, were not impressed by the delicacy of his surgery, and would defer emergency cases admitted for a few hours so they would come under someone else's care. You won't find this written down, but will hear it directly from interns and surgical registrars working there at the time.

Unfortunately the design of the needleholder also confirmed my adage that "habit is more powerful than logic". Using this needleholder required getting used to a different habit of work. Despite the advantages of the design did not match the perceived difficulty of learning to use it.

-o0o-